|

|

|

![]()

THE MARQUETRY CUTTING KNIFE

|

We always suggest that you start by cutting shapes. Carefully check your test pieces for any major faults in order to correct your technique for your project work.

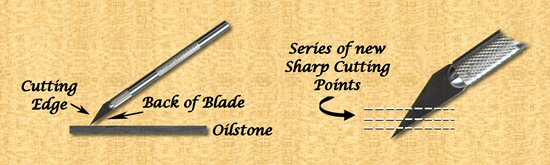

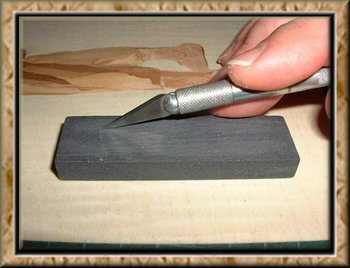

Of all the skills required in marquetry without doubt, the main one is the ability to cut accurately. This skill depends on maintaining a sharp point on the knife. The point of the blade is the part of the knife which is used to cut not the long edge of the blade. To maintain this point the blade is sharpened on fine carborundum stone or oilstone, as shown below (Fig. 1). |

|

|

|

|

|

Return to top of page | Return to "How's it Done?" menu page |